Robotic Product Loading System

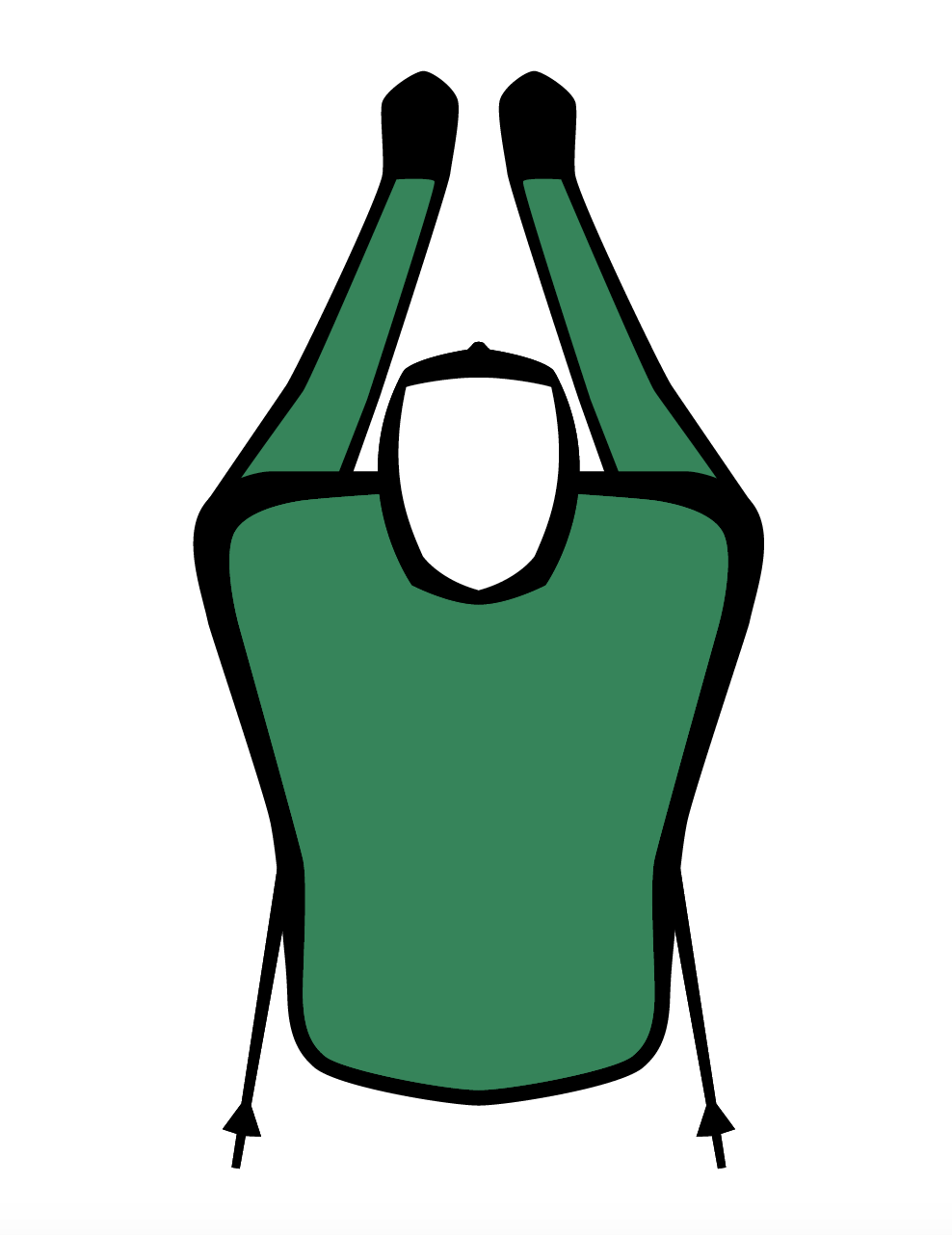

This project involved the automated loading of products onto Fanuc robots from bulk packaging in a harsh environment where machine vision was not reliable. The system I designed and built entails a scanning algorithm and laser tool for the robot as well as custom product packaging (early prototype shown). The flexible algorithm first acquires key product and packaging dimensions via the laser sensor, accommodating a range of packaging and product variations. From these dimensions, the locations of all products are calculated. Products are then picked sequentially from the packaging by the robot. The laser tool design features a spring plunger for repetitive coupling, axial alignment of the laser beam and robot end effector, and locating features for mating with the tool holder. The packaging was designed to be durable, stackable, and configurable based on robot cell footprint constraints and product needs. This project was developed utilizing a Fanuc robot cell that I designed and built, including the cell layout, safety and control systems, and robot programs.